NEWS&EVENTS

Home > News&Events > Company news > How to treat the high-temperature flue gas generated from smelting antimony ore in a rotary furnace?

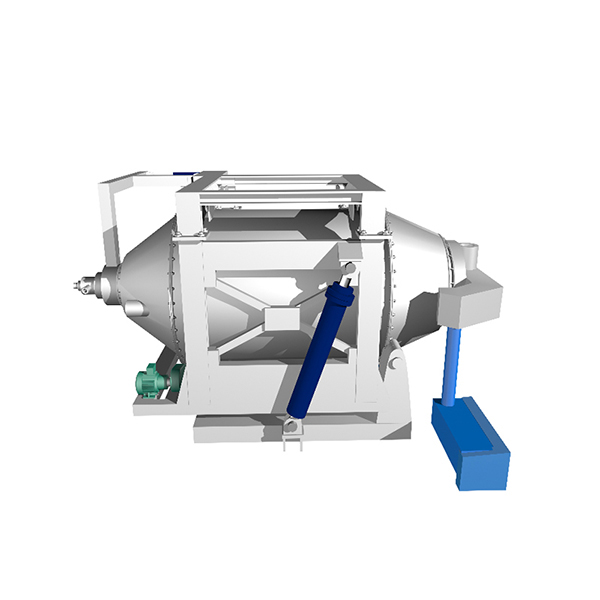

In the pyrometallurgical process of antimony ore, the rotary furnace is one of the core equipment. When ore is melted at high temperatures in the furnace, not only does it produce metallic antimony, but it also generates a large amount of complex and high-temperature flue gas. If these fumes are directly emitted, they will cause serious environmental pollution and resource waste. Therefore, establishing an efficient and systematic flue gas treatment process is the key to achieving green smelting, meeting emission standards, and comprehensive resource utilization.

The first stage is a circular flue, and the high-temperature flue gas just discharged from the rotary furnace carries a large amount of smoke and dust, which will directly enter the subsequent equipment and damage the equipment. The circular flue collects and guides the flue gas, which is initially cooled through natural heat dissipation and forced air cooling, laying the foundation for subsequent purification.

The second level is the dust removal system. The cooled flue gas enters the dust collector, which uses an efficient bag filter to separate and capture solid particles. Antimony dust can be sold after treatment, achieving resource recovery, reducing emission concentration, and creating economic benefits.

The third level is the desulfurization tower. After dust removal, the main pollutant in the flue gas is sulfur dioxide. The flue gas in the desulfurization tower reacts with the absorbent to produce sulfates, which are removed and ultimately discharged as clean gas to meet emission standards.

From the cooling of the high-temperature annular flue, to the efficient dust collector for recovering valuable resources, and then to the thorough purification of the desulfurization tower, this coherent flue gas treatment system vividly illustrates how modern metallurgical industry transforms environmental pressure into the driving force of technological upgrading and resource efficiency enhancement.