NEWS&EVENTS

Home > News&Events > Company news > Energy-saving and consumption-reducing strategies for rotary furnaces in antimony smelting.

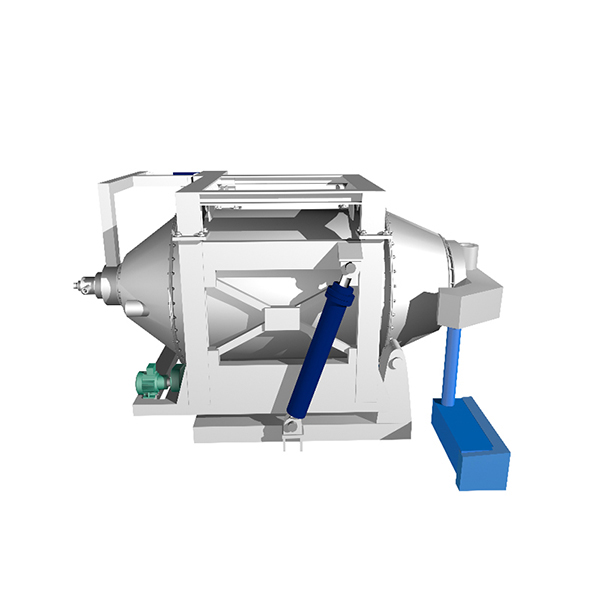

In the continuous production process of antimony smelting rotary furnace, energy conservation and consumption reduction are not only the key to reducing production costs, but also the inevitable requirement for enhancing enterprise competitiveness and achieving sustainable development. As a manufacturer of rotary furnaces, we are well aware of the importance of energy conservation and consumption reduction. Below, we will introduce effective methods from two aspects: operational measures and equipment improvement.

In terms of operational measures, precise temperature control is the core of energy conservation and consumption reduction. We suggest setting the temperature range accurately based on the reaction characteristics of the material and adopting advanced temperature control systems to avoid heat waste caused by excessive temperature and achieve precise temperature control. Meanwhile, it is also crucial to control the furnace drum speed reasonably. If the speed is too fast, it will increase energy consumption, while if it is too slow, it will affect the material reaction. It is necessary to find the optimal equilibrium point to allow the material to fully react in the furnace. In addition, optimizing the feeding speed and amount cannot be ignored. Ensure that the materials inside the furnace are in the optimal reaction state, avoiding excessive or insufficient impact on thermal efficiency, thereby reducing unnecessary energy consumption.

In terms of equipment improvement, our furnace lining adopts new insulation materials, effectively reducing heat loss and improving the insulation performance of the furnace body. Improving the combustion device is also the key to enhancing energy efficiency. By optimizing the design and improving combustion efficiency, the fuel can be fully burned to release heat and reduce fuel consumption. In addition, installing waste heat recovery devices is another important measure for energy conservation and consumption reduction. It can recover and utilize the waste heat emitted by the furnace body, which can be used to preheat materials or provide heat required for other production processes, achieving energy recycling.

Through the above operational measures and equipment improvement methods, the energy-saving and consumption reducing goals in the continuous production process of antimony smelting rotary furnaces will be effectively achieved, helping enterprises reduce costs and increase efficiency, and achieve green and sustainable development.