NEWS&EVENTS

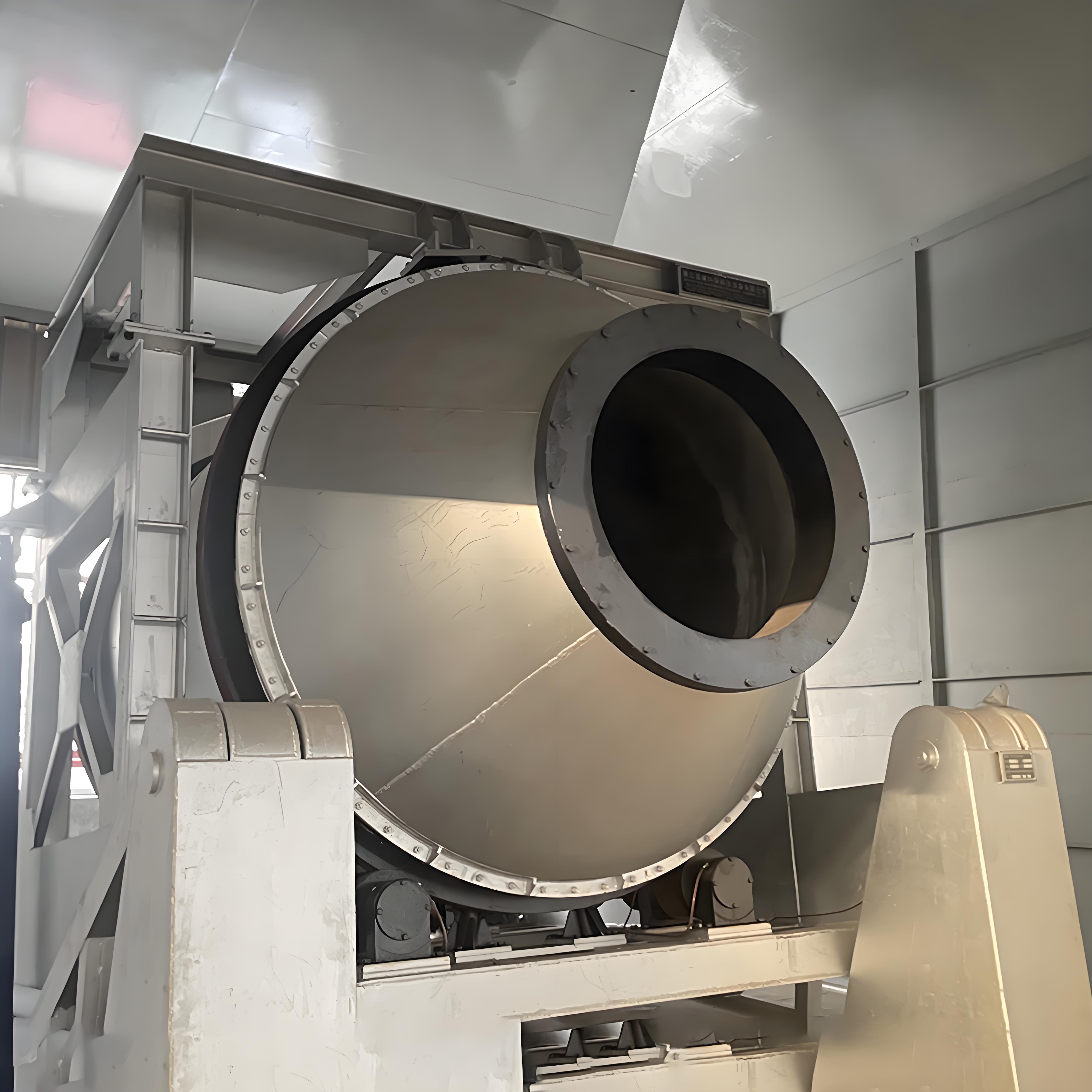

Home > News&Events > Company news > What erosion will the lining of the rotary furnace withstand during antimony smelting?

In the process of smelting antimony, the lining of the rotary furnace will face various erosion, which seriously affects its service life and smelting effect. Mainly withstand the following types of erosion:

① Chemical erosion

This is the main form of erosion. The antimony oxide (Sb ₂ O3) slag generated during antimony smelting has strong alkalinity and can cause severe chemical dissolution and erosion of acidic or neutral refractory materials. At the same time, sulfur and volatile sulfide vapors (such as Sb ₂ S3) in the raw materials will penetrate into the internal pores and matrix of refractory materials, generating new compounds, resulting in loose lining structure, decreased strength, and even bulging and peeling.

② Physical erosion

Mechanical wear and erosion: During the rotation of the rotary furnace, solid furnace materials (ore, flux) and liquid melt continuously roll, causing continuous mechanical friction and erosion with the surface of the furnace lining, resulting in material surface wear and thinning.

Thermal shock peeling: Due to intermittent operations or temperature fluctuations, the furnace lining repeatedly undergoes rapid cooling and heating, resulting in significant thermal stress inside. When the stress exceeds the material strength, it can cause cracking and surface peeling of the furnace lining.

High temperature creep: Under long-term high temperature action, refractory materials will undergo slow plastic deformation, leading to instability of the furnace structure.

Given these erosion factors, when selecting refractory materials for rotary furnaces, it is important to consider multiple aspects of performance. To have high fire resistance and ensure stability in high-temperature smelting environments; Good resistance to slag erosion and chemical corrosion from slag; High thermal shock stability, reducing peeling caused by temperature changes; High strength and wear resistance to withstand mechanical wear of materials, thereby extending the service life of furnace lining and ensuring the smooth progress of antimony smelting.