NEWS&EVENTS

In the production process of high-quality antimony trioxide powder, there are special and strict requirements for the equipment and operation of the oxidation and collection links.

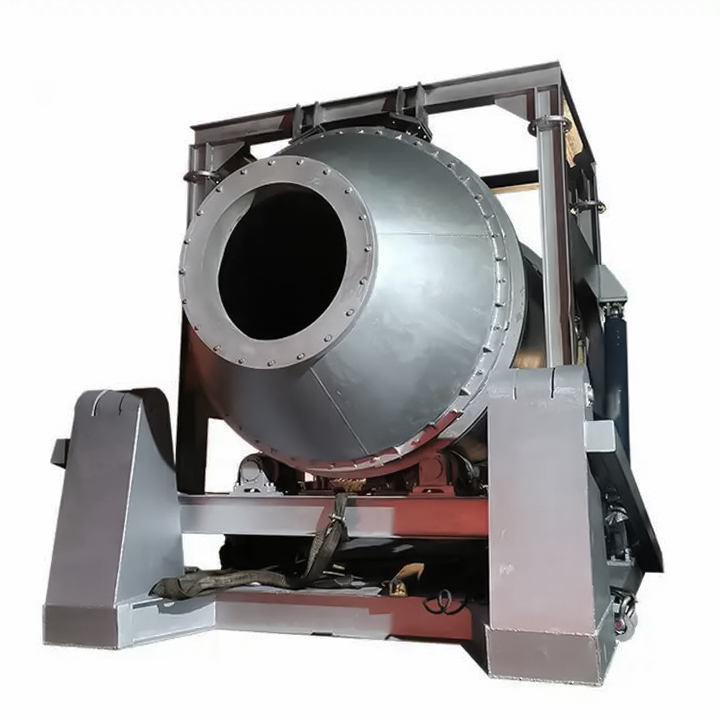

The oxidation process is the basis for determining product quality. This process needs to be carried out in a refining furnace (oxidation furnace), and precise control of the oxidation atmosphere and temperature is key. A suitable oxidizing atmosphere can provide sufficient oxygen elements to fully oxidize antimony to form antimony trioxide. The control of temperature affects the rate of reaction and the morphology of the product. Excessive temperature may lead to oversized product particles, while insufficient temperature may result in incomplete reaction. Only precise regulation can ensure the complete oxidation of antimony and promote its full volatilization, laying the foundation for the subsequent collection of high-quality products.

The collection process cannot be ignored either. Due to the high purity and fineness of antimony trioxide powder generated during the oxidation process, it requires excellent performance of the dust removal system. Bag filter is a commonly used collection equipment, which needs to have good high temperature resistance to adapt to working in high temperature environments. Meanwhile, sealing performance is also crucial. Good sealing can prevent product leakage, prevent external impurities from entering, and ensure the purity of the product. Only by efficiently capturing antimony trioxide powder can high-quality final products be obtained.

In short, precise control of the oxidation process and reliable equipment for the collection process are essential conditions for obtaining high-quality antimony trioxide powder.