NEWS&EVENTS

Home > News&Events > Company news > Core control strategies for smelting high-quality antimony in rotary furnaces.

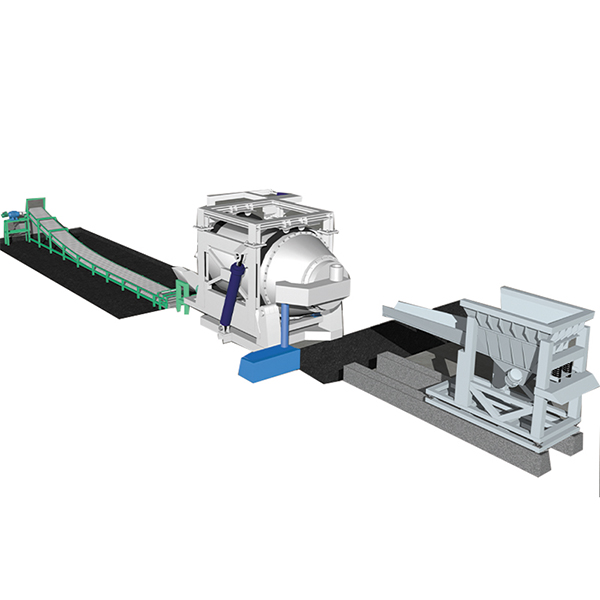

In the pyrometallurgical process of antimony smelting, rotary kilns have become a key piece of equipment for processing antimony concentrates and producing crude antimony due to their efficient heat and mass transfer, continuous operation, and good material adaptability. Their smelting performance and product quality highly depend on the precise control of smelting temperature and feeding rate.

Precise temperature control is crucial for the reduction reaction and the quality of crude antimony. The smelting temperature inside the rotary kiln is the driving force for the reduction chemical reaction and requires strict control. Too low a temperature results in incomplete reduction reactions, increased antimony content in the slag, decreased metal recovery rate, and poor melt fluidity; too high a temperature exacerbates furnace lining erosion, shortens equipment lifespan, and may lead to antimony volatilization losses and product contamination. A stable and uniform furnace temperature is the cornerstone for obtaining high-purity, high-recovery crude antimony. Modern rotary kiln systems establish a stable "thermal field" through multi-stage temperature measurement, intelligent combustion control, and optimized insulation design.

Uniform feeding is fundamental to maintaining stable furnace conditions. The feeding rate is like controlling the pace of "ingredients" delivery; continuous, stable, and uniform feeding is a prerequisite for maintaining thermal and material reaction equilibrium. Interruption or fluctuation in feeding disrupts stable furnace conditions, causing thermal shock, affecting yield, compositional stability, and equipment safety, leading to inconsistent product quality across batches. A reliable, precise, and controllable feeding system is indispensable.

As a rotary kiln manufacturer, we are committed to integrating advanced temperature measurement technology, intelligent combustion control systems, and highly reliable feeding devices into our equipment design and manufacturing, providing customers with complete solutions that enable precise thermal management and stable material flow, ensuring the smelting of high-quality crude antimony and stable, efficient production.