NEWS&EVENTS

Home > News&Events > Company news > The role of antimony refining furnaces in the production of antimony oxide powder.

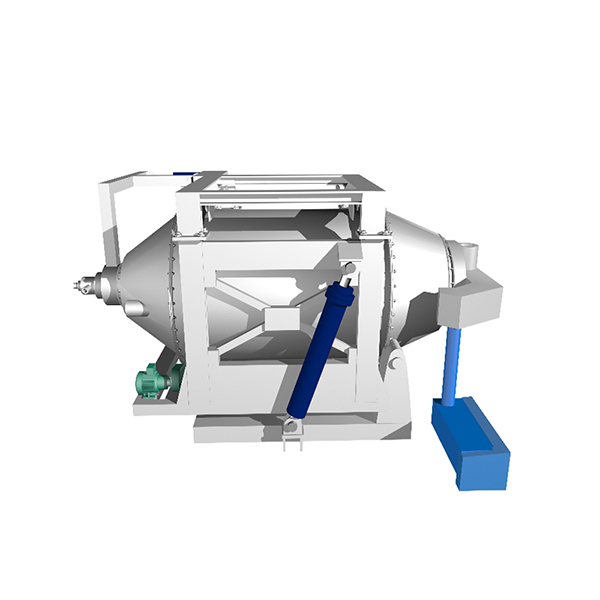

In the production process of antimony oxide powder, the efficient and controlled conversion of molten antimony metal into high-purity antimony trioxide (Sb₂O₃) is a critical core step. This oxidation reaction takes place in an antimony refining furnace (oxidation furnace). As a professional manufacturer of antimony refining furnace equipment, we understand that a high-performance oxidation furnace is the cornerstone of large-scale, economical production of high-quality antimony oxide powder.

The core function of the refining furnace is to create an ideal oxidation reaction environment. It brings the high-temperature molten antimony, after initial refining, into full contact with precisely controlled air or oxygen-enriched air. Under a specific fluid dynamics design and temperature field distribution, the surface of the molten antimony undergoes vigorous oxidation, releasing antimony trioxide vapor. This process is a precise physicochemical process, requiring the furnace structure to ensure uniform reaction, sufficient gas-liquid contact, and stable and controllable temperature. Our oxidation furnaces are designed around these requirements, optimizing the furnace chamber structure, selecting high-quality refractory materials, and equipping them with precise air supply and temperature control systems to ensure continuous and efficient oxidation reactions.

The technological value of our oxidation furnace equipment is significant: high oxidation efficiency, a unique furnace design and air distribution system improve the antimony oxidation rate and direct yield, impacting capacity and profitability; excellent product quality, a stable temperature field and smooth airflow reduce side reactions, facilitating the production of high-quality antimony oxide powder, laying the foundation for high-end applications; and good operability and environmental friendliness, ensuring stable and easy operation, reducing metal volatilization losses and environmental pollution, and achieving clean production.

In short, the antimony refining furnace is the core converter connecting antimony metal with high-value-added antimony oxide products. Its technological level determines production efficiency, product quality, and the core competitiveness of the enterprise. We are committed to providing our customers with technologically advanced and reliable antimony refining furnace solutions, contributing to the high-quality development of China's antimony smelting industry.