NEWS&EVENTS

Home > News&Events > Company news > High-purity antimony ingot production: Pyrometallurgical equipment solutions

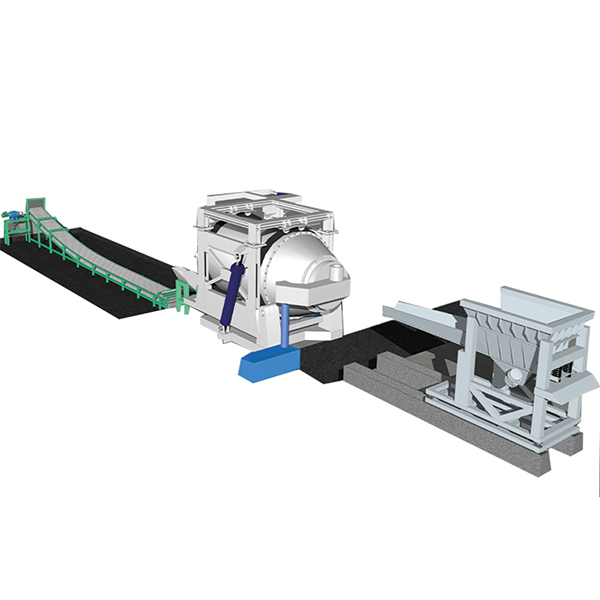

For antimony ingot producers, we offer a complete process package and core equipment solutions from raw materials to finished products, ensuring stable production of high-purity antimony ingots. The complete process chain includes core equipment such as: feeding system → rotary kiln (desulfurization) → rotary furnace (reduction smelting) → refining furnace → continuous casting machine & ingot stacking machine, etc. This chain covers all key stages of antimony production, with each piece of equipment seamlessly connected to form an efficient and controllable continuous production line.

I. Rotary Furnace: The Key Guarantee for High-Quality Crude Antimony

The rotary furnace is the core link in ensuring the quality of the final product. Its function is to reduce the desulfurized antimony oxide powder into high-quality crude antimony suitable for refining.

Our rotary furnace ensures crude antimony quality through several design features:

Precise temperature control system: Using multi-zone temperature control and intelligent temperature control modules to ensure uniform and stable furnace temperature and complete reduction reaction.

Dynamic sealed feeding: Prevents air ingress, reduces secondary oxidation of the metal, and guarantees metal recovery rate.

Optimized molten pool depth and rotation speed: Enhances melt stirring, promotes impurity flotation and separation, and improves crude antimony purity.

Slag type control system: Effectively captures impurities through composition adjustment, producing clean crude antimony liquid.

II. Complete Line Planning and Process Package Support

We not only provide core rotary furnace equipment but also plan and provide key upstream and downstream equipment for our customers:

Upstream equipment: Precise feeding machine, rotary kiln desulfurization system, flue gas treatment and dust collection system

Downstream connection: Refining furnace equipment selection, continuous casting unit configuration, automated ingot stacking and packaging line

Auxiliary systems: Complete flue gas treatment solutions, waste heat recovery system, automated control system

III. Professional Service Advantages

We provide full-process services from process design and equipment manufacturing to installation and commissioning, ensuring seamless connection of each equipment unit to form an efficient and environmentally friendly complete production line. Whether it's a new project or a technical upgrade, we can tailor the most suitable antimony ingot production solution based on the customer's ore characteristics and production capacity requirements.

Choosing us means you get not just a piece of equipment, but complete production assurance from ore to antimony ingot product.