NEWS&EVENTS

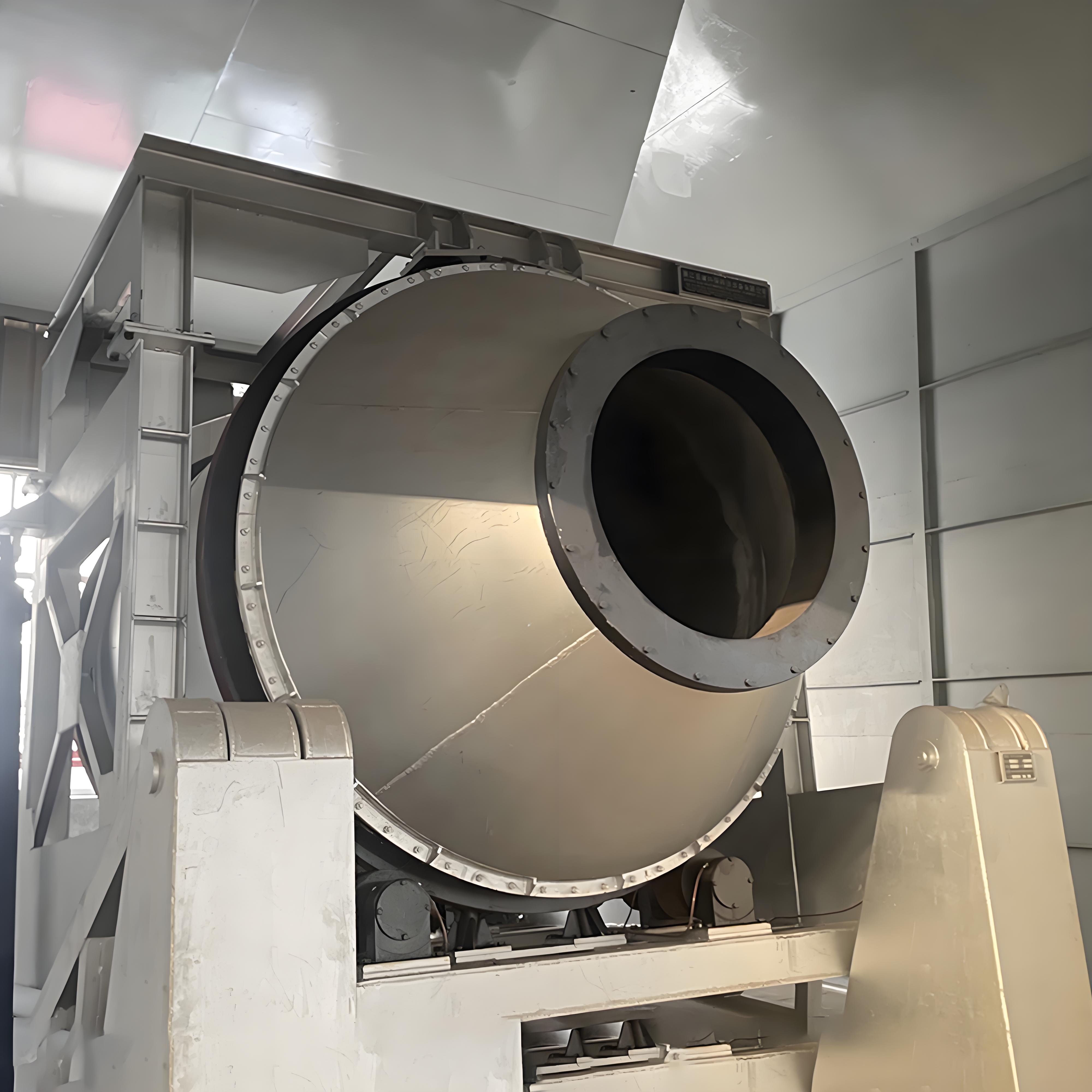

Home > News&Events > Company news > Key points for extending the service life of refractory materials in aluminum melting rotary furnaces.

Extending the lifespan of refractory materials in aluminum melting rotary furnaces is crucial for ensuring production continuity and reducing production costs. Damage to refractory materials is usually the result of the combined effects of thermal stress, mechanical stress, chemical corrosion, and improper operation.

The following are five key operational points, covering the entire process from operation to maintenance:

I. Strict Furnace Heating and Start-up/Shutdown Procedures

When heating a new furnace or after relining with new bricks, the heating process must follow the specified temperature curve, especially in the 300℃~600℃ and above 1200℃ stages. Rapid heating should be avoided to prevent cracking and spalling. Planned shutdowns should involve slow cooling with insulation, while unplanned emergency shutdowns require maintaining slow rotation of the furnace body to prevent brick fragmentation. Restarting a cold furnace requires slow heating to ensure uniform heating and expansion of the refractory materials.

II. Stable Thermal and Flame Control

Adjust the burners to ensure a regular flame shape, avoiding direct impingement on the rotary aluminum melting furnace shell and refractory bricks. Maintain stable temperature in the rotary aluminum melting furnace system to prevent large fluctuations and excessive peak temperatures that exacerbate melting damage and thermal shock spalling. Avoid strong reducing atmospheres in the rotary aluminum melting furnace to prevent brick loosening and damage.

III. Maintaining a Stable Furnace Lining

Optimize the material mix and operation to promote the formation of a lining of appropriate thickness and uniform stability. Prevent frequent lining detachment, as this can cause the surface layer of the refractory bricks to spall off. Address abnormal lining conditions to prevent collapse, which can cause mechanical impact or localized overheating.

IV. Strengthening Equipment and Mechanical Maintenance

Regularly check the furnace body centerline and adjust the support rollers to prevent severe deformation of the furnace body. Maintain a stable furnace speed to ensure even material coverage and minimize temperature fluctuations. Reduce the number of start-ups and shutdowns to prevent periodic thermal stress from accelerating refractory material fatigue damage.

V. Standardized Process Operation and Monitoring

Maintain stable feeding, and reasonably adjust the rotary aluminum melting furnace speed and feeding rate. Use an infrared scanner to monitor the surface temperature of the rotary aluminum melting furnace cylinder, conduct regular internal inspections, and record the condition of the refractory bricks. Pay attention to abnormal process parameters and respond promptly. Integrate these operational points into daily procedures and train operators to extend the lifespan of the rotary aluminum melting furnace refractory materials and achieve cost reduction and efficiency improvement.