NEWS&EVENTS

Home > News&Events > Company news > Technical characteristics of pyrometallurgical antimony ore process

The modern pyrometallurgical process for antimony ore has developed into a highly integrated, efficient, energy-saving, and environmentally friendly system engineering. Through precise processes and advanced technology control, it achieves efficient conversion of ore into multiple products while reducing energy consumption and pollution.

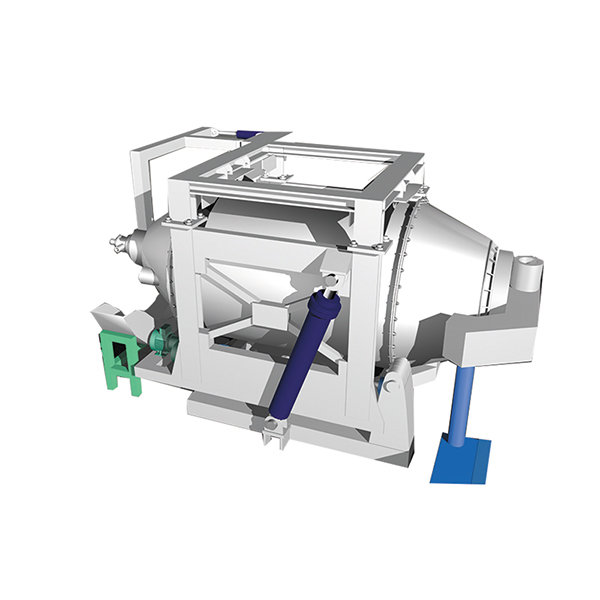

The significant feature of this process is the energy cascade utilization and system integration. With the rotary furnace as the core, it not only completes the high-temperature reduction smelting of crude antimony reaction, but also transports the waste heat to the rotary kiln to provide heat for the roasting process, greatly reducing external energy consumption.

Strong flexibility in raw material processing and product output. The same system can adjust the production path as needed, refine and continuously cast metal antimony ingots, control oxidation volatilization and bag dust collection to obtain high value-added antimony trioxide powder, and enhance the market adaptability of enterprises.

Smelting flue gas treatment integrates resource recovery and environmental protection governance. The high-temperature flue gas is first collected by a dust collection system, which is rich in antimony trioxide, to recover valuable components, and then enters purification processes such as desulfurization to ensure that the exhaust gas meets the standards.

The core reaction of the process relies on precise control of high-temperature and strong reduction conditions, which requires extremely high levels of operation management and automation, and is the key to ensuring metal recovery rate and product quality.

The entire process, from continuous feeding to automatic stacking, is highly continuous and mechanized, reducing production fluctuations, improving efficiency and stability, laying the foundation for intelligence.

In short, modern antimony pyrometallurgy integrates energy conservation, resource utilization, environmental protection and emission reduction production, and is a complex and efficient system, marking a profound evolution of antimony smelting technology towards green, intelligent and sustainable directions.