NEWS&EVENTS

Home > News&Events > Company news > What is the purpose of high-temperature roasting of antimony ore in a rotary kiln?

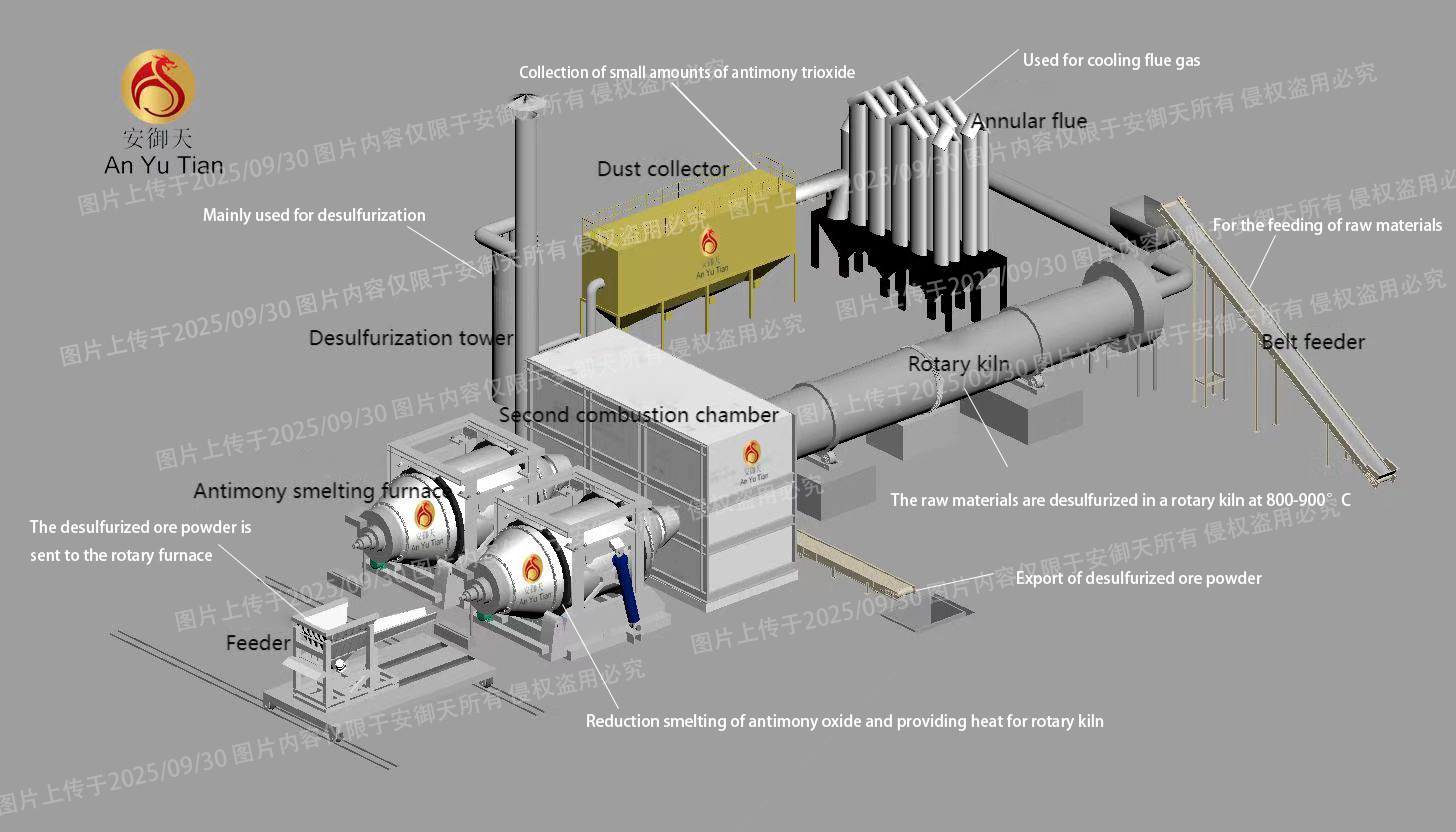

The core purpose of high-temperature roasting of antimony ore at 800-900 ℃ in a rotary kiln is "desulfurization". Specifically, this is a chemical process that removes sulfur elements from ores through oxidation reactions.

The main purpose and process are as follows:

Chemical reaction (oxidation roasting):

Antimony ore (mainly stibnite, with a chemical composition of antimony disulfide, Sb ₂ S ∝) reacts in a high-temperature aerobic environment. Sulfur is oxidized into sulfur dioxide gas and released, while antimony is converted into an oxide that is easy to refine later.

This reaction will transform antimony sulfide, which is difficult to directly reduce, into antimony trioxide (Sb ₂ O3), which is more easily reduced by carbon or carbon monoxide.

2. Implemented functions and importance:

Preparation for Reduction Smelting: The generated antimony oxide (Sb ₂ O3) is more easily reacted with reducing agents (such as coke) in the next rotary furnace process and reduced to metallic antimony. This is much more efficient and energy-efficient than direct reduction of antimony sulfide.

Recycling sulfur elements (or reducing pollution): The generated sulfur dioxide (SO ₂) gas is collected centrally and can be used for acid production, achieving resource utilization. Even without acid production, effective treatment (such as subsequent desulfurization towers) must be carried out, which is a crucial environmental step to avoid the formation of acid rain.

Improving metal recovery rate: Thoroughly desulfurizing can ensure the smooth progress of subsequent smelting and increase the final output and purity of antimony metal.

Summary: The roasting process in a rotary kiln is a key pretreatment step for "conversion and impurity removal". It separates the "sulfur" in the ore into gas through oxidation desulfurization, and at the same time converts the "antimony" from sulfide form to more easily extractable oxide form, laying the foundation for efficient and environmentally friendly production of metallic antimony in the future.