NEWS&EVENTS

In the pyrometallurgical antimony refining process, after obtaining crude antimony metal, the production process enters the refining stage and splits into two independent paths, producing the final antimony ingot and antimony trioxide powder respectively, reflecting the flexible production characteristics of "same source diversion".

The production of antimony ingots aims to obtain high-purity solid metals. Firstly, crude antimony is refined by adding refining agents to the refining furnace, and impurities such as iron, lead, and arsenic are further removed in a molten state to obtain pure antimony solution. Subsequently, the antimony liquid is fed into a continuous casting machine for casting and solidification into standard sized antimony ingots after cooling. Finally, the finished product packaging is completed through automatic stacking and bundling by a robotic arm. The core of this path lies in physical forming, and its iconic equipment is the continuous casting machine and automated ingot stacking system.

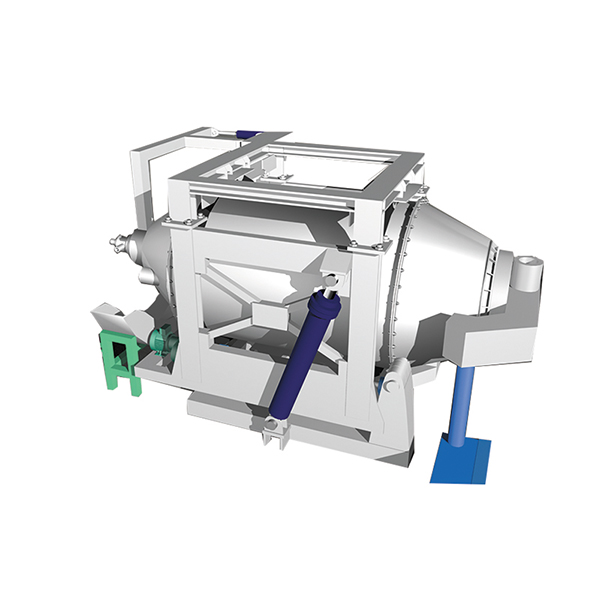

The production of antimony trioxide powder aims to obtain high-purity white powder. The refined antimony liquid reacts strongly with excess air in an oxidation furnace and evaporates at high temperatures above 900 ℃, producing gaseous antimony trioxide. Subsequently, the high-temperature flue gas is rapidly cooled, causing antimony trioxide to condense into fine particles, which are then efficiently collected by a dedicated bag filter to become coarse products. Finally, the product powder is obtained through screening, packaging, and other post-processing. The core of this path is chemical conversion and gas-solid control, and the key equipment is the oxidation volatilization furnace and its supporting product collection system.

The two paths start from a common crude antimony raw material and refining process, with a branching point in the subsequent processing selection of pure antimony liquid: one is to cast it into a metal ingot, and the other is to oxidize and evaporate it and condense it into oxide powder. This flexible process design enables enterprises to efficiently adjust the output of different forms of ultimate products according to market demand, fully demonstrating the adaptability and economy of pyrometallurgical antimony refining technology.