NEWS&EVENTS

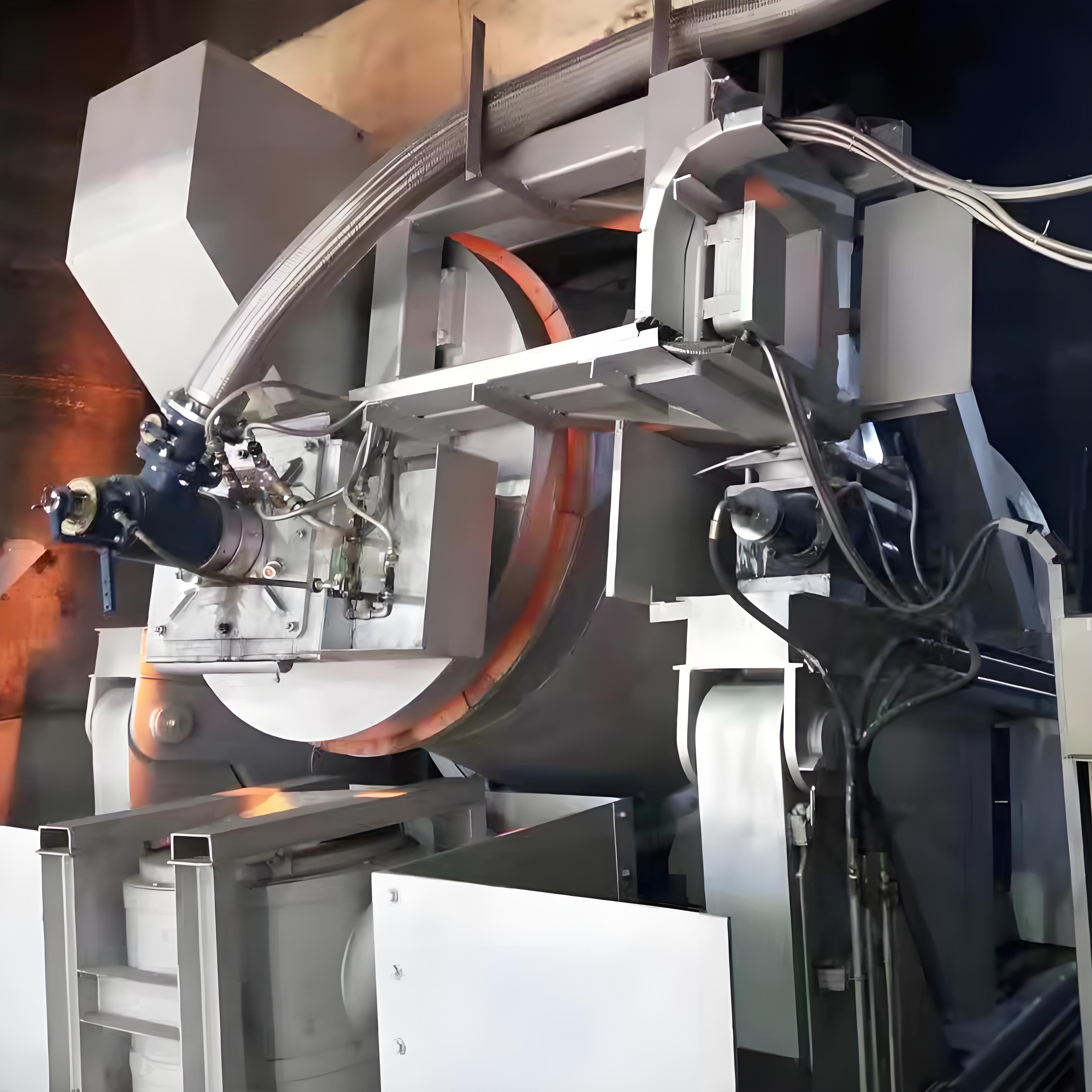

The tilting furnace is a key piece of equipment in non-ferrous metal smelting (such as copper and lead). It uses a tilting mechanism to control the discharge of molten metal and the overall process. Its main components are as follows:

1. Tilting Furnace Body: Consists of the furnace body (a melting pool constructed with refractory materials), the furnace shell (steel structure support), and the tilting mechanism (hydraulic or mechanical drive system). It carries out the smelting process and can tilt from 0° to 90° to discharge the molten metal. It is also equipped with a combustion system and monitoring devices.

2. Launder System: Includes an inclined trough (lined with refractory materials), flow control devices (stopper rods or gates), and a support frame. It guides the molten metal to downstream equipment, regulates the flow to prevent splashing and blockage, and some systems include heating elements to prevent solidification.

3. Rotary Casting Machine: Composed of a rotating disc, mold assembly, cooling system, and demolding device. It casts the molten metal into standard ingots in a quantitative manner. The disc rotates for continuous operation and is equipped with an automatic ingot handling robot.

4. Dust Collection System: Includes a fume hood, flue, dust collector (electrostatic precipitator or bag filter), induced draft fan, and chimney. It collects and purifies the dust before discharge, and some systems integrate waste heat recovery devices.

5. Flue and Exhaust System: Consists of high-temperature resistant flues, expansion joints, gate valves, and exhaust fans. It connects the furnace body to the dust collection system, regulates the flue gas flow, maintains negative pressure inside the furnace, and has an emergency discharge port.

6. Auxiliary Equipment: The feeding system enables automated material feeding; the hydraulic system provides power for furnace tilting; the cooling water system provides circulating cooling for key components; and the automated control system monitors parameters.

Application Scenarios: In copper smelting, it processes matte to produce cathode copper; in lead smelting, it melts crude lead, and the dust collection system captures lead-containing dust, with the flue gas being discharged to a desulfurization unit. The tilting furnace equipment combination is designed around the core process and works collaboratively. The actual configuration is adjusted according to process requirements.