NEWS&EVENTS

Home > News&Events > Company news > Process control and weight accuracy assurance during copper tapping from a tilting furnace.

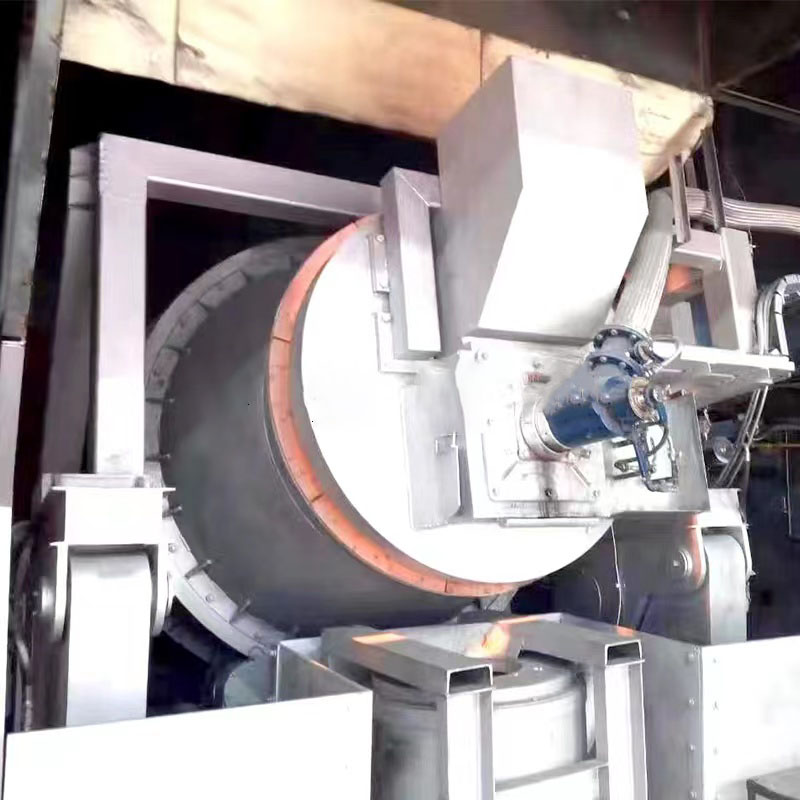

The copper tapping process of the tilting furnace is precisely controlled through the following steps to ensure accurate molten copper weight:

1. Tilting Control

The furnace body is slowly tilted by a hydraulic system, allowing the molten copper to flow smoothly into the quantitative casting ladle through the tapping spout. The tilting speed is adjustable to prevent splashing or interruption of the molten copper flow.

2. Online Weighing Monitoring

A high-precision weighing sensor is installed below the casting ladle to display the molten copper weight in real time. The data is transmitted synchronously to the control system for dynamic monitoring.

3. Automatic Stop and Return

When the real-time weight approaches the set value, the system automatically slows down the tilting speed; once the target weight is reached, the hydraulic system immediately returns to its original position, stopping the copper tapping.

4. Accuracy Assurance Measures

Regular calibration: The weighing system is calibrated daily to eliminate errors.

Flow channel design: The structure of the tapping spout and flow channel is optimized to reduce the impact of residual molten copper on the weight measurement.

Temperature compensation: The influence of density changes on weight calculation due to molten copper temperature is corrected.

5. Manual Verification and Emergency Response

Operators can use visual observation and manual intervention to assist in control and respond to emergencies (such as sensor failure), ensuring safety and accuracy.

Through the above closed-loop control, combined with automation technology and manual supervision, the weight error of the molten copper tapped from the tilting furnace can usually be controlled within ±0.5%, meeting the production requirements of high-quality cast billets.