NEWS&EVENTS

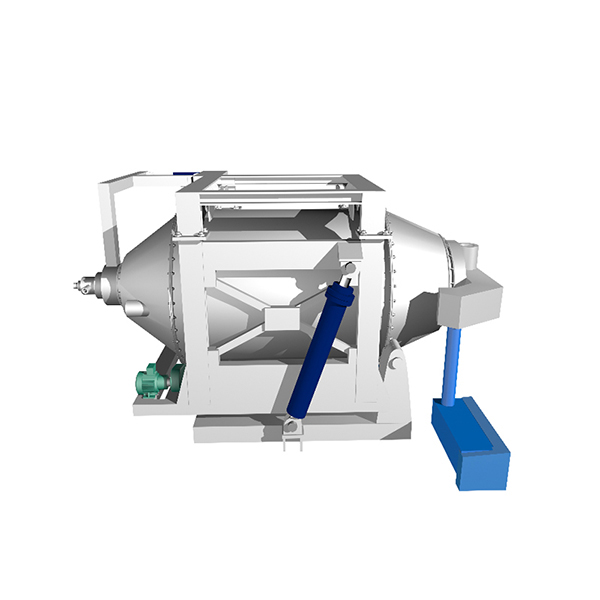

Home > News&Events > Company news > Methods for ensuring uniform temperature of molten antimony in a rotary refining furnace.

During the refining of antimony liquid in a rotary refining furnace, ensuring uniform temperature and avoiding local overheating or undercooling is crucial. This can be achieved through the following aspects:

Optimizing the stirring device design

A well-designed stirring device is key to promoting uniform temperature in the antimony liquid. The shape, size, and installation position of the stirring paddles must be carefully designed to generate a suitable flow field during rotation, promoting sufficient flow of the antimony liquid within the furnace. For example, using multi-layered, multi-angled stirring paddles can enhance the stirring effect, allowing the antimony liquid at different locations to mix, breaking down local temperature differences, and enabling rapid and uniform heat transfer, thus avoiding temperature dead zones.

Uniform distribution of heating elements

The rational layout of the furnace heating system significantly impacts the uniformity of the antimony liquid temperature. Heating elements should be evenly distributed around and at the bottom of the furnace body to ensure that all parts receive similar heat input. Simultaneously, using heating elements with stable performance and uniform heat generation ensures that they continuously and stably release heat during operation, avoiding local overheating or undercooling caused by differences in the heating elements themselves.

Precise temperature control system

Equipping a precise temperature control system is central to ensuring stable antimony liquid temperature. Multiple high-precision temperature sensors are installed at different locations within the rotary refining furnace to monitor the antimony liquid temperature in real time. The control system analyzes the data fed back by the sensors and precisely adjusts the heating power. When a certain area is detected to be too hot, the power of the corresponding heating element in that area is reduced; if an area is too cold, the power is increased, ensuring that the antimony liquid temperature remains stable within the appropriate process range, effectively preventing local overheating or undercooling, and ensuring the smooth refining process and stable product quality.