NEWS&EVENTS

Home > News&Events > Company news > What equipment is involved in the process of refining molten antimony from the antimony refining furnace into antimony ingots?

In the field of antimony production and processing, the transformation of refined antimony liquid from the antimony refining furnace into antimony ingots is a highly automated and continuous industrial marvel, showcasing the intelligence and precision of modern metallurgical industry.

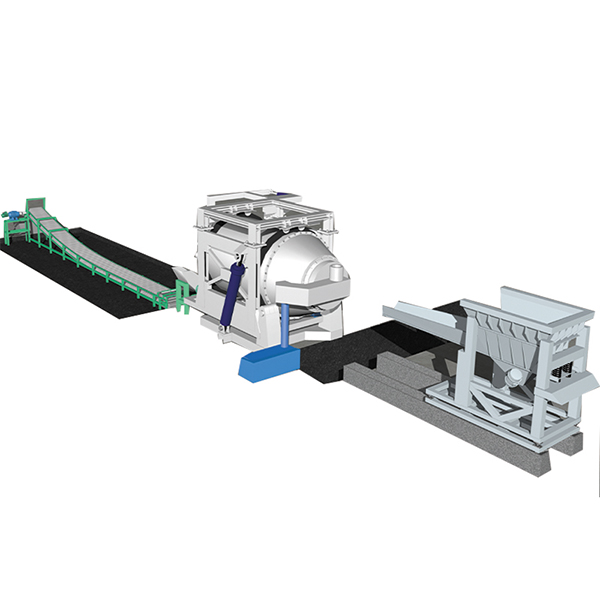

In the antimony refining furnace, pure antimony liquid is produced through a series of complex processes. This molten antimony then enters a continuous casting machine, beginning its continuous casting journey. The continuous casting machine, like a skilled craftsman, precisely controls parameters such as temperature and speed, skillfully shaping the antimony liquid into hot ingots, laying the foundation for subsequent processes.

As soon as the hot antimony ingots are formed, a robotic stacking machine quickly takes over. With its flexible robotic arm, it automatically grasps the hot ingots and stacks them precisely, completing the process seamlessly. This process is not only highly efficient but also greatly reduces manual intervention, ensuring production safety. The stacked antimony ingots are then sent to a bundling machine, where they are professionally bundled and packaged, officially becoming antimony ingot products.

Throughout the entire process, in addition to the continuous casting machine and the robotic stacking machine, auxiliary equipment such as the cooling system and conveying system also play a crucial role. The cooling system ensures rapid cooling of the antimony ingots, while the conveying system ensures the smooth flow of materials at each stage.

Through the collaborative operation of the antimony refining furnace and these devices, automated assembly line production is achieved, with a production capacity of several tons per hour, greatly improving production efficiency. At the same time, automated production ensures product consistency and safety, providing stable, high-quality antimony ingot raw materials for downstream applications, widely used in battery alloys, flame retardant materials, and other fields.