NEWS&EVENTS

Home > News&Events > Company news > What are the key performance requirements for the design of the furnace door of a rectangular aluminum melting furnace?

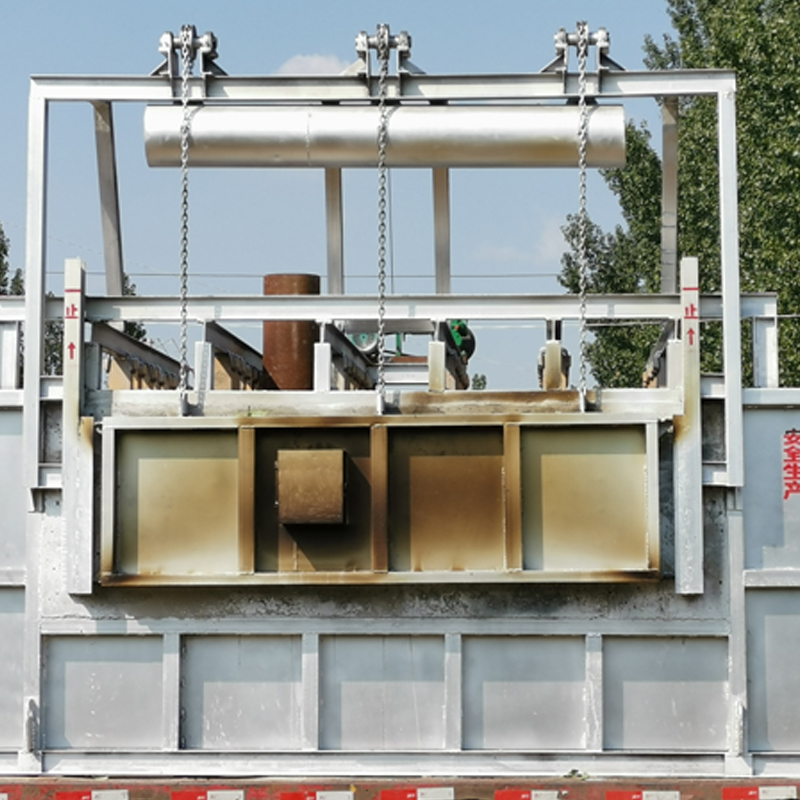

In the manufacturing of rectangular aluminum melting furnaces, the furnace door design is crucial, as its performance directly impacts the overall operation and production quality of the furnace. Sealing performance and structural strength are the two core performance requirements.

Sealing performance is the primary consideration in the design of rectangular aluminum melting furnace doors. The furnace operates at high temperatures, and poor sealing will lead to significant heat loss, resulting in considerable energy waste and increased production costs. It will also cause temperature fluctuations inside the furnace, affecting the quality of the molten aluminum and the melting efficiency. Furthermore, the intrusion of cold air can disrupt the thermal balance inside the furnace, potentially leading to increased oxidation of the molten aluminum and the generation of more impurities. To address this issue, we employ sealing materials that maintain stable sealing performance in high-temperature environments, effectively preventing heat transfer and cold air intrusion, ensuring stable furnace temperature, and providing a favorable thermal environment for aluminum melting.

Structural strength is equally important. The furnace door of a rectangular aluminum melting furnace needs to be opened and closed frequently, and the door frame is subjected to considerable mechanical stress during this process. Moreover, the high temperature inside the furnace causes thermal expansion and deformation of the frame material. If the structural strength is insufficient, the frame is prone to damage and deformation, preventing the door from closing properly and affecting the sealing performance. Therefore, we meticulously design the furnace door frame structure, selecting high-strength, high-temperature-resistant alloy materials. Through reasonable structural layout and reinforcement design, we enhance the frame's resistance to mechanical stress and high-temperature deformation, ensuring that the furnace door operates stably even under frequent opening and closing and high-temperature conditions, providing a solid guarantee for the long-term reliable use of the rectangular aluminum melting furnace.