NEWS&EVENTS

Home > News&Events > Company news > How to choose an efficient and energy-saving rotary furnace for antimony smelting?

Currently, numerous antimony smelters are facing common challenges: high overall energy consumption, frequent fluctuations in the direct recovery rate of crude antimony, significant waste of high-temperature flue gas waste heat, and poor matching of equipment with upstream and downstream processes, which hinders overall efficiency improvements. The key to solving these systemic problems often lies in the advanced design concepts and superior system integration capabilities of the core equipment—the rotary furnace.

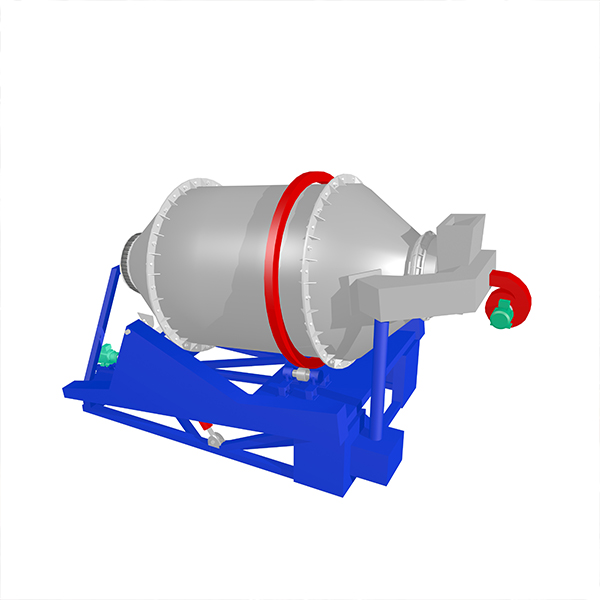

A superior rotary furnace is not merely a standalone unit, but rather a "master of energy cycling" that reshapes the economics of smelting. It should efficiently integrate reduction smelting with heat supply to the upstream rotary kiln, utilizing a unique combustion system and heat exchange design to achieve cascaded and recycled thermal energy. This is expected to help customers significantly reduce overall fuel costs. Simultaneously, precise and stable control of the temperature and atmosphere within the furnace is crucial for ensuring efficient antimony reduction and volatilization, improving metal recovery rates, and minimizing slag loss. Furthermore, excellent interface design (such as sealed feeding, reliable discharge, and flexible flue gas connections) makes it a "system coordination hub," ensuring seamless integration with upstream and downstream processes and enabling stable, continuous automated production.

In terms of technical implementation, the differences lie in the details. Critical components require special heat-resistant materials and alloys to withstand high-temperature corrosion and wear, extending their lifespan. An advanced intelligent control system should be able to precisely control parameters such as temperature, pressure, and rotational speed, and support remote monitoring and diagnostics, empowering the "smart factory." Environmental performance must also be built in, reducing air leakage and suppressing nitrogen oxide generation through optimized design, thus alleviating the pressure on end-of-pipe treatment.

In short, an excellent rotary furnace is essentially the "energy center," "efficiency engine," and "profit generator" of a smelter. As an equipment manufacturer with many years of experience in antimony smelting, we not only provide equipment but are also committed to sharing comprehensive process optimization solutions based on our extensive practical experience. Every rotary furnace we produce embodies our deep understanding of the process. If you require a customized design tailored to your specific raw materials and product requirements, our team of technical experts is ready to provide professional support.