NEWS&EVENTS

Home > News&Events > Company news > Structure and performance characteristics of rotary antimony refining furnaces

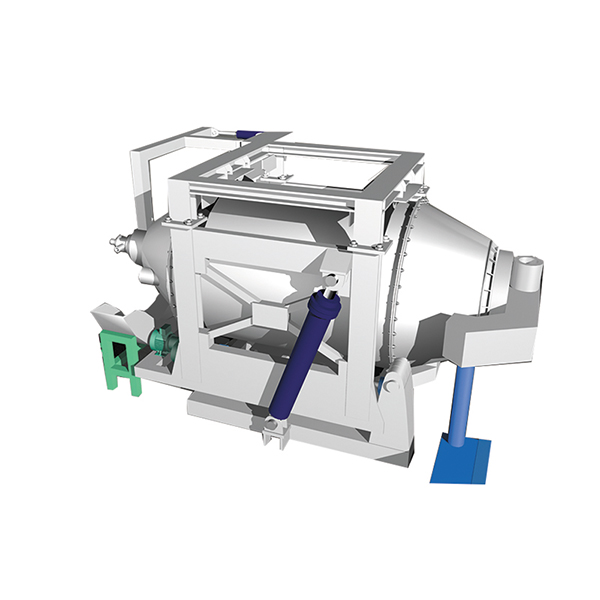

In the complex process of producing antimony ingots and antimony trioxide from antimony ore, the refining/oxidation furnace is the final critical link for product separation. Our rotary refining furnace is a comprehensive metallurgical furnace capable of integrating both refining (slagging) and oxidation (volatilization) processes. The refining/oxidation furnace integrates multiple functions, with the following structural and performance characteristics:

1. The furnace body adopts a cylindrical or rectangular design, lined with high-grade refractory materials, capable of withstanding high temperatures, with excellent airtightness and a large furnace chamber to meet the needs of refining, slagging, and antimony liquid volatilization.

2. The combustion and heating system is equipped with independently adjustable gas or oil burners. The refining mode maintains a neutral or weakly reducing temperature field of 900-1000℃; the oxidation mode increases the heating intensity, precisely controlling the temperature at 1000-1200℃, providing energy for the sublimation of antimony trioxide.

3. The air supply and exhaust system is the core of process switching. During refining, external air supply is shut off or minimized, and slagging is achieved through stirring or adding refining agents; during oxidation, a strong air supply device is activated, and the exhaust channel is connected to a high-efficiency bag filter system to create negative pressure, allowing gaseous antimony trioxide to rapidly volatilize and be extracted.

4. The temperature and atmosphere monitoring system monitors temperature and gas composition in real time, enabling precise process switching.

The rotary antimony refining furnace integrates the two processes of refining and oxidation, saving equipment investment and space, and can efficiently and economically produce high-purity antimony ingots and antimony trioxide powder alternately, reflecting an efficient, flexible, and environmentally friendly integrated design.