NEWS&EVENTS

Home > News&Events > Company news > High-efficiency antimony ore smelting equipment rotary furnace professional manufacturer

Driven by the global green energy transition and industrial upgrading, antimony, as a critical strategic resource, is experiencing continuously increasing market demand. Widely used in flame retardants, lead-acid batteries, semiconductors, and other fields, antimony is entering a significant growth cycle. However, behind this market growth lies a serious challenge for traditional antimony smelting technologies: high energy consumption, low production efficiency, and increasing environmental pressure. More and more companies urgently need modern, efficient, energy-saving solutions that fully comply with environmental standards to enhance their competitiveness and achieve sustainable development.

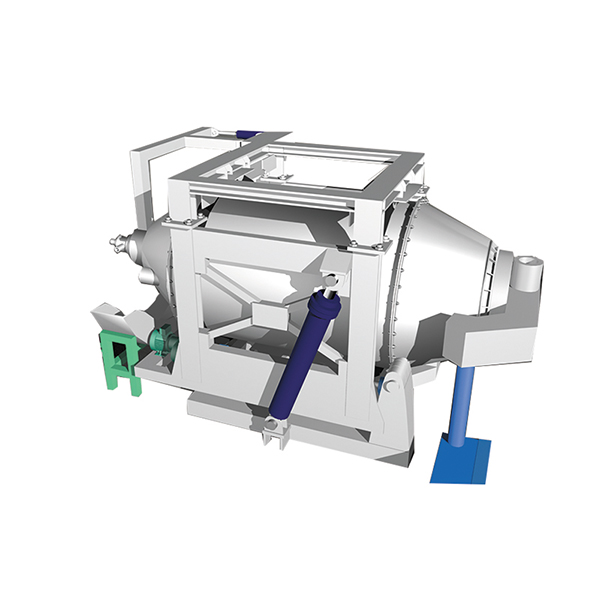

Addressing this core pain point, our rotary kiln has emerged as a key piece of equipment for upgrading antimony smelting. It is specifically designed for the primary smelting of antimony ore and the production of antimony oxide:

1. High-efficiency heat utilization: The unique internal structure design significantly improves heat exchange efficiency, saving energy compared to traditional equipment and reducing operating costs.

2. Intelligent control: Equipped with an advanced PLC automation system, it achieves precise monitoring and automatic adjustment of key process parameters such as temperature and rotation speed, ensuring product stability and consistency.

3. Leading environmental protection: Integrated with a high-efficiency dust removal and flue gas treatment system, it ensures that emission indicators strictly meet standards, supporting our customers' green production.

Why choose us? Because we offer more than just equipment; we offer value. We understand that each customer has different ore characteristics and production capacity goals, so we provide deeply customized solutions, matching your actual needs from the design stage.