NEWS&EVENTS

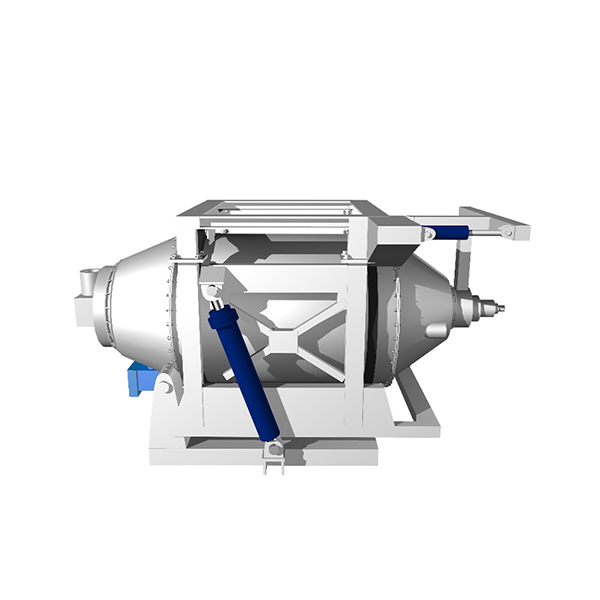

Home > News&Events > Company news > Antimony refining furnace: Refining effectiveness and key points of quality control

To ensure the refining effect and product quality stability of the antimony refining furnace, systematic control is required in raw materials, process, equipment, and management, forming a closed-loop quality assurance system. The following are the key control points:

I. Raw Material Pretreatment and Composition Control

The chemical composition of crude antimony directly affects the difficulty and effectiveness of refining. The crude antimony should be analyzed for its composition in advance, and the type and amount of refining agents should be adjusted accordingly based on the types and content of impurities. If the raw material composition fluctuates significantly, it needs to be stabilized through blending or pretreatment to create consistent reaction conditions for subsequent refining.

II. Optimization of Key Parameters in the Refining Process

1. Refining Agent Control: Select appropriate refining agents based on the type of impurities and accurately calculate the amount to be added. The agents should be added in batches and at multiple points, combined with mechanical or gas stirring to promote sufficient contact between the agent and the molten antimony, thereby improving reaction efficiency.

2. Precise Temperature Control: Establish a temperature segmented control system. Avoid excessively high temperatures during the melting stage to prevent oxidation losses; control the temperature within a suitable range during the refining reaction stage to ensure efficient impurity removal; and appropriately lower the temperature before tapping to reduce metal volatilization. Use thermocouples and an automatic temperature control system for real-time monitoring and adjustment.

3. Time Management: The refining time needs to be matched with the temperature and the addition of refining agents. Determine the optimal time range through experiments and adjust flexibly based on online monitoring.

In addition, regular maintenance and inspection of the refining furnace are necessary to ensure normal operation of the equipment and prevent equipment failures from affecting the refining effect and product quality.